Do you know how much fiber tension are you applying to the laminate during your GRP pipe production?

Keeping the fiber tension constant throughout the whole lamination process is one of the essential properties of the winding machine.

But due to the fact that the production speed is gradually increased after the start up, the hoop fiber tension also gets modified.

I am sure that you did notice such problem in your CFW machine especially if you are using the simplest and less effective manual fiber tensioner.

And the questions that arise are:

1. How do you know if you are applying the correct hoop fiber tension?

2. And if you finally get the “perfect pipe”, how do you know how much tension you applied?

Our customers already know the answers because they are using our PLC fiber tension control saving up to USD 100.000/month.

Imagine that your Plant is producing a pipe with a weight of 600 kg/m and that you are producing at an average rate of 10 m/hour. This means 6.000 kg/hour. Simple math.

Addressing only the raw material cost (I will not consider the raw material handling and financial costs), we could easily say that your cost is 5.500 USD/hour (yes, I know, it also depends on the pipe pressure and stiffness, but let’s assume an average situation).

Ok, so now let’s take a production scenario with a raw material cost of 5.500 USD/hr = 132.000 USD /day.

Now, let’s assume that we will produce continuously for 20 days.

132.000 USD/DAY x 20 DAYS = 2.640.000 USD/20 days.

And now let’s imagine that you upgrade your equipment and get a 5% saving:

2.640.000 USD/20 DAY x 5% = 132.000 USD/20 DAYS

🚩 SAVINGS OF 132.000 USD IN 20 DAYS!

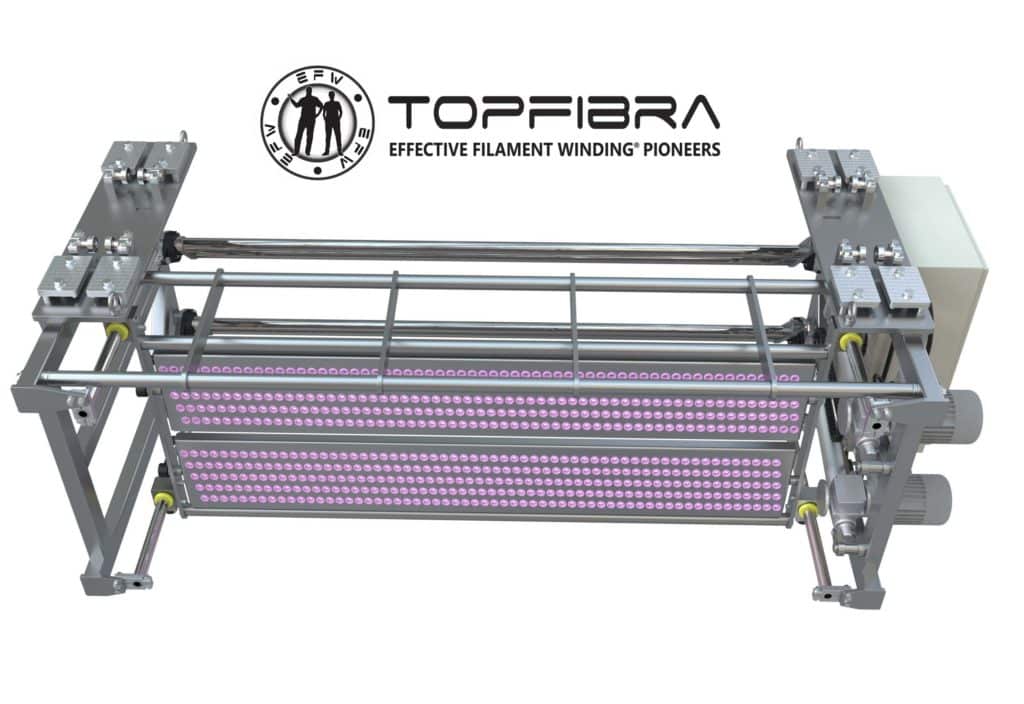

If you are asking yourself if we could install it in your existing CFW machine, the answer is:

YES, we can install it in your CFW machine “stand alone”!

Moreover, if you measure and control your Hoop Fiber tension during the production, you will avoid:

- Resin overdosing, causing higher costs and lower pipe technical specifications;

- Fiber buckling;

- Possible delamination.