Avoid tears on the liner by compromising the water tightness of the pipe with our new E-AD4000 high performance accelerator system

The most regular occurrence of pipe damages is seen during the cutting of a pipe, in the final rotation cycle. The difference in relative rotation during the cutting, between the pipe that is being produced and the pipe that will be discharged after the cutting, will cause a tear on the liner, compromising the water tightness of the pipe, and a possible breakage of the cutting blade if not handled correctly.

The repair to be carried out on the liner in this case would be a very delicate operation and would, in any case, prejudice the aesthetics and increase the risk of rejection by the end-user.

Of course, with an increase in the diameter of the pipe, this relative velocity problem will increase exponentially, thereby increasing the risk and severity of liner tears.

I am sure that you did notice such problem in your CW machine, especially if you are using the simplest and less effective accelerator model found on the market: the pneumatic accelerator.

The pneumatic accelerator has the following disadvantages:

- It does not have speed control; thus, it is not able to guarantee the circumferential speed after the cutting;

- It does not have torque control; thus, it cannot be regulated for the production of both heavy and light pipes;

- The mechanical system that moves the accelerator toward the pipe is not precise, thus the light pipes do not remain stable during the cutting operation which leads to imprecise cutting.

How did we solve it?

To avoid the problems mentioned above we upgraded and designed the E-AD 3000 ACCELERATOR replacing the old pneumatic motor with an electrical motor implementing:

-

- Speed control to match perfectly the circumferential speed;

- Torque control to avoid any slippage;

- Belt driven system to avoid the chain stretching and related maintenance;

- Horizontal slider with brake system;

Due to the success of our E-AD3000, we decided to design a new generation accelerator.

You are probably asking yourself what else could TOPFIBRA have further improved on the previous version of the E-AD3000?!

Let’s review the improvements together.

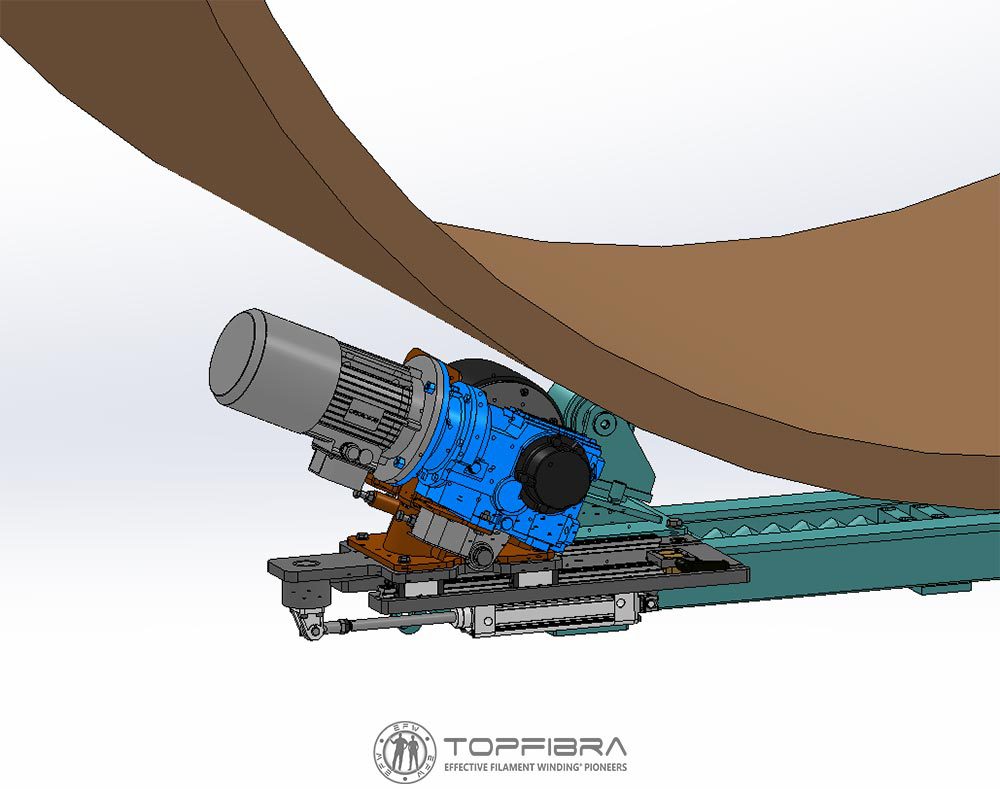

To summarize, it is possible to install this accelerator even on an EFW® 400-4000 winder!

-

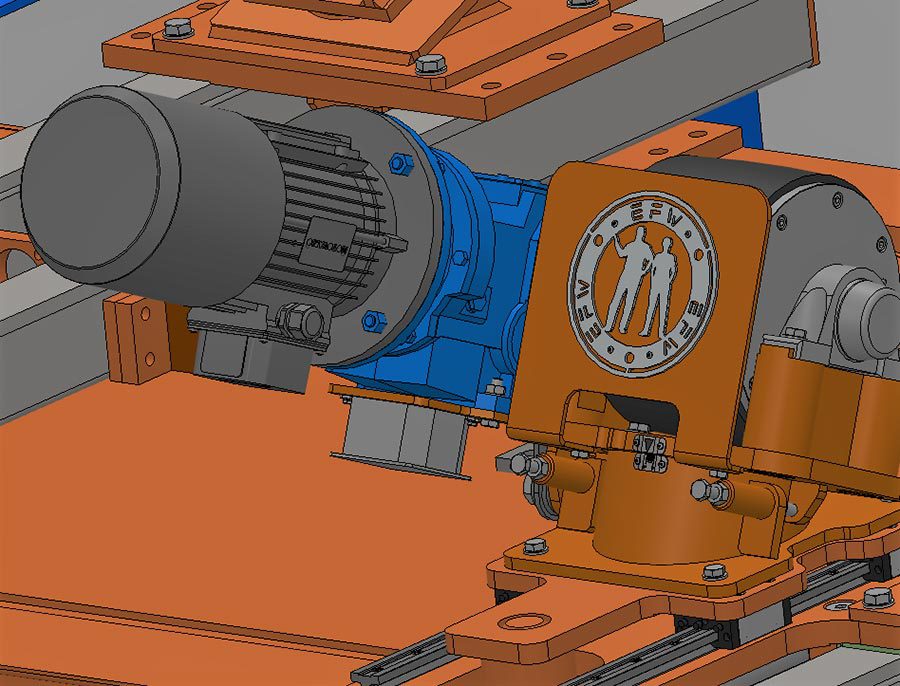

- Direct transmission: now the transmission does not even need the belt. One part less to care about during maintenance, no need for the belt adjustment checks, instantaneous speed self-adjustment;

- Bigger rubberized wheel: to increase the surface area of contact between the accelerator and the pipe for a better grip. As you know, depending on the inclination of the accelerator and the external curvature of the pipe, the contact area varies, so we decided to increase the security factor for the most demanding situations;

- Stronger clutch: inside the wheel for heavy duty work;

- Increased force: against the pipe for heavy duty production. The pressure piston, pressure regulated, is doubled compared to the previous one. Of course, we kept the independent brake to avoid that smaller pipes (especially small diameters) are jolted by the approach and positioning;

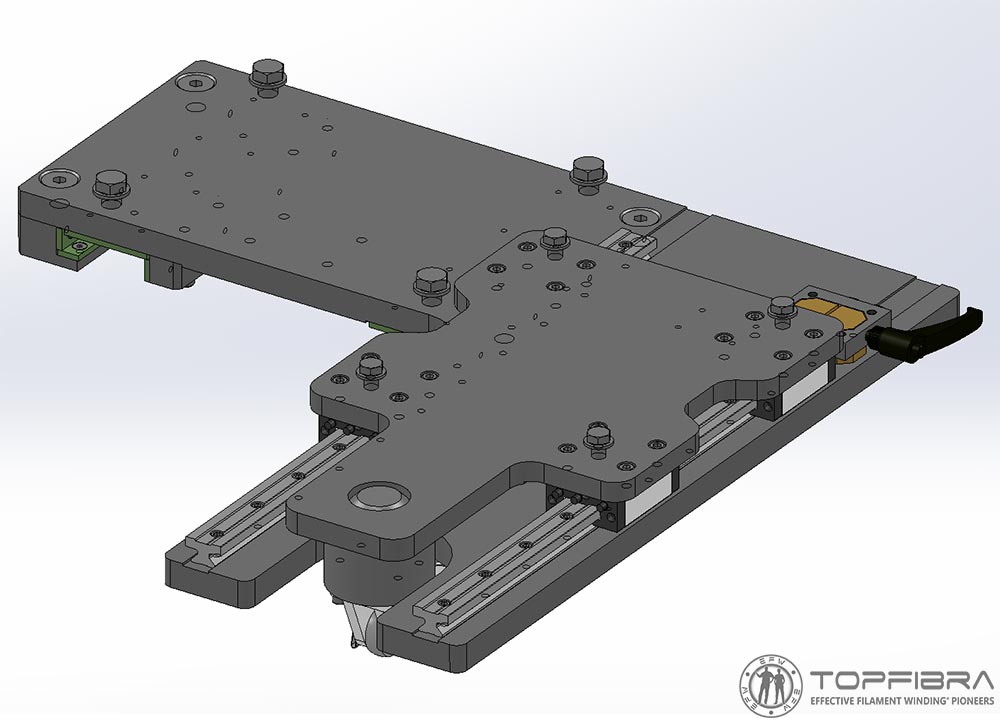

- Longer linear guides: to increase the stroke and the application range of the accelerator.

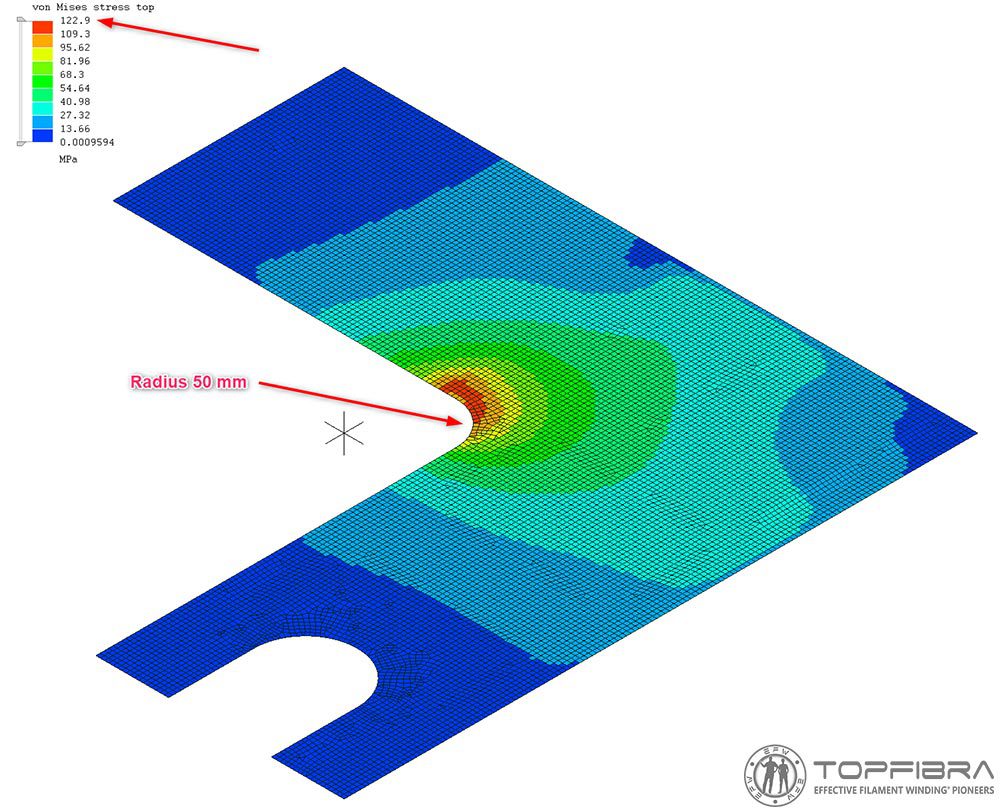

Fem calculation of the latest generation HIGH PERFORMANCE E-AD4000 ACCELERATOR

To avoid any unexpected variables during heavy-duty working loads, we have performed a fem calculation of the underplate and slider.

We have changed the radius as indicated in the picture, reducing the max stress by about 120 N/mm2.

Conclusion

Using the latest generation E-AD4000 HIGH PERFORMANCE ACCELERATOR, production will benefit from:

-

- Immediate response for the torque and speed PLC adjustment;

- Improved contact between the rubberized wheel and pipe, due to the bigger wheel;

- Heavy duty performance due to a stronger jack for better pressure applied to the pipe and stronger clutch;

- Easier replacement of the rubberized wheel, due to self-adjusting assembly;

- Longer adjustment stroke for the biggest pipe range.